LISA WMS for SAP BUSINESS ONE – Release Highlights 25.1

Earlier this year our development team has released LISA WMS Version 25.1. This latest update introduces innovative features designed to empower warehouse operators and enhance operational flexibility, particularly focusing on scenarios where operator-led sequencing can significantly boost efficiency. Read on to discover how these new modules and improvements for our premier SAP Business One warehouse companion can further streamline your processes.

Introducing the Flexible Picking Non-Directed (ND) Module

We understand that sometimes the most efficient picking sequence isn’t strictly system-dictated. Certain situations, like needing to stack products on a pallet from heaviest to lightest for stability, benefit from operator expertise. To support this, we’ve introduced the Picking Non-Directed (ND) module.

Here’s how it works:

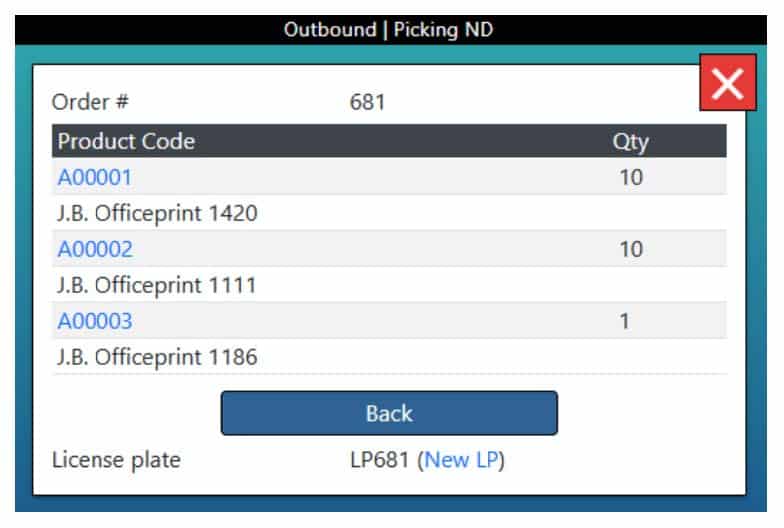

- When picking begins for an order or group using the ND module, the operator sees a list of all required products.

- The operator selects the product they wish to pick next based on their judgment (e.g., the heaviest item first).

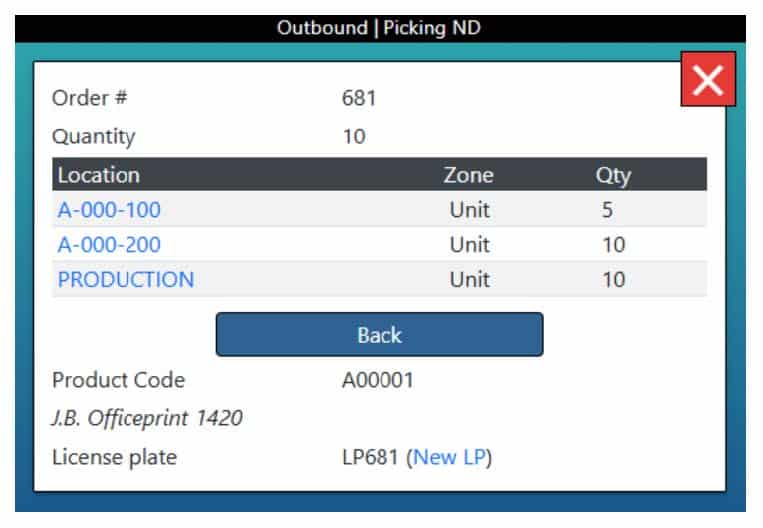

- The system then displays the specific locations where that selected product is available.

- Upon arriving at the chosen location, the operator scans the location bin to confirm.

- Optionally, the system can be configured to require a product scan, adding an extra layer of verification to ensure the correct item is picked.

This approach blends operator knowledge with system guidance for accuracy.

Product Selection

Location Selection

Benefits of the Picking Non-Directed Module

- Boosted Efficiency: Empowers operators to choose the optimal picking sequence for specific scenarios (like pallet building), potentially speeding up the process.

- Increased Flexibility: Adapts to unique operational needs where a fixed system path isn’t ideal.

- Empowered Workforce: Leverages the experience and situational awareness of your warehouse team.

- Maintained Accuracy: Incorporates mandatory location scans (and optional product scans) to prevent errors despite the flexible sequence.

Streamlined Storage: The New Put Away by Product Module

Similar to picking, optimizing the put away sequence can significantly impact efficiency. Unloading a pallet often flows best by putting away the items accessible first (e.g., top-down). The new Put Away by Product module facilitates this operator-driven approach.

The process is straightforward:

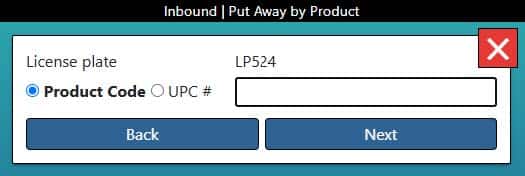

- The operator initiates the put away by scanning the license plate (LP) of the goods to be stored.

- Next, they scan the specific product they intend to put away from that LP.

- LISA WMS then guides the operator to the appropriate storage location(s) for that specific product.

This method allows operators to follow a natural workflow, like unloading a pallet layer by layer, while still benefiting from system-directed placement into the correct final bin.

Benefits of the Put Away by Product Module

- Optimized Put Away Flow: Allows operators to sequence put away based on the physical arrangement of goods (e.g., unloading pallets efficiently).

- Enhanced Efficiency: Can reduce unnecessary handling and movement by aligning the system process with the natural workflow.

- Operator Empowerment: Gives control to the operator to handle items in the most logical physical order during put away.

- Guided Accuracy: Ensures items reach their correct, system-designated storage locations even with a flexible sequence.

Other Improvements of LISA 25.1

Beyond the new modules, Version 25.1 includes several valuable improvements:

- Improved LISA Web Interface: The warehouse list and edit pages in LISA Web have been enhanced for better usability.

- Enhanced Zone Visibility: Product category restrictions assigned to zones are now clearly displayed on the zones list page in LISA Web, improving clarity

- Aligned Bin Capacity: The maximum bin capacity setting in NLoader has been increased to match LISA WMS, ensuring consistency.

- Production Receipt Validation: A new control ensures that a production receipt process requires at least a partial pick to have been completed beforehand.